R & D

R & D, Manufacturing

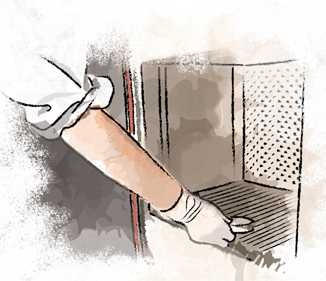

Cleaning

Thoroughly removing the stain and pesticide residue from the vegetables and fruits

Selection

Remove vegetables and fruits that are too small or come with damage on the surface and only select the finest vegetables and fruits

Crushing

Crush all fruits and vegetables evenly

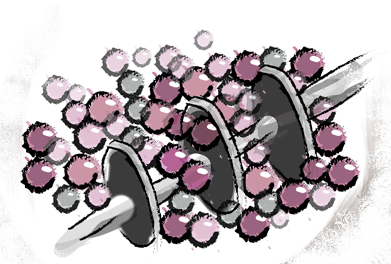

Fermentation

Humidity and temperature auto-monitoring system Maintaining the excellent environment for microbial fermentation

storage

ndependent storage fermentation barrel Only long-term brewing will extract the essence

Ancient fermentation

Adopting different key fermentation factors such as material, air proportion, bacterial properties, concentration, and cellulose sediment to build the best fermentation environment for one hundred types of vegetables and fruits, brewing the fermentation liquid with mellow and healthy taste

Filling

Auto-filling technology for bottle sealing

bottle sealing

Auto sealing package

Quality Control Test

Sugar content Test

Quality Control Test -01

PH value Test

Quality Control Test -02

Sterile Platform

Quality Control Test – 03

Incubator

Quality Control Test – 04